Our

Commitment

Our Beliefs

We believe...

- The Carbon Cycle is a naturally sustainable process and dairying will be part of the GHG solution.

- Animal agriculture is fundamental to responsibly and sustainably feeding our planet.

- Water is a precious resource and must be treated as such.

- Healthy cows, productive farms, and efficient production are the levers within our control that can help us achieve our sustainability goals.

- Dairy products provide superior nutrition and are beneficial through all life stages

- In being leaders in safety, quality and food security.

- In positively impacting our suppliers, customers, community and employees.

- Farmers should get the credit for making sustainability improvements on the farm.

U.S. Dairy Stewardship

Commitment

We’re committed to responsible dairy production and improving the communities we serve. That’s why we’re proud to have adopted the U.S. Dairy Stewardship Commitment, which affirms our dedication to sustainable practices. We are determined to be leaders in the dairy and farming effort to achieve greenhouse gas neutrality by 2050 and use our expertise to create innovative solutions that contribute to a sustainable future.

Supporting the

Net Zero Initiative

We are determined to be leaders in the dairy farming effort to achieve greenhouse gas neutrality by 2050. We use our expertise to create innovative solutions that contribute to a sustainable future.

Committed to Change

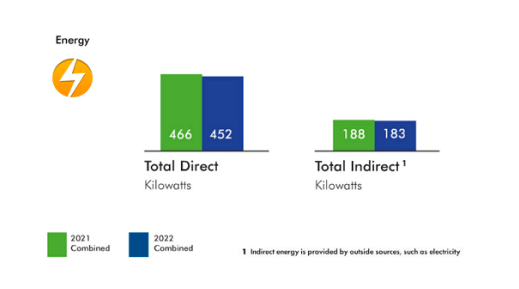

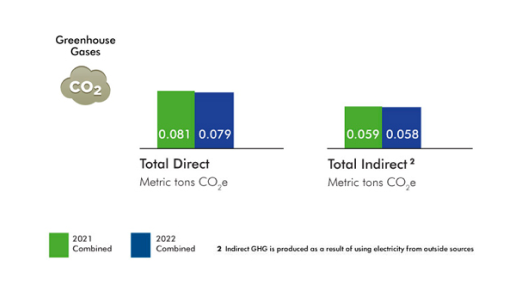

Energy

Our goal is to reduce energy use per 1,000 pounds of product which has decreased since 2021.

Greenhouse Gases

Our goal is to decrease the amount of greenhouse gas (GHG) direct emissions per 1,000 pounds of product and we have decreased since 2021.

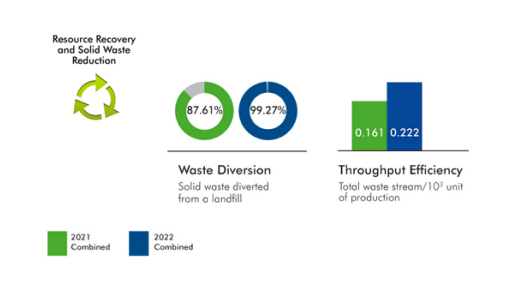

Resource Recovery

Our goal is to minimize resource use and maximize reuse and recycling. We improved waste diversion in 2022.

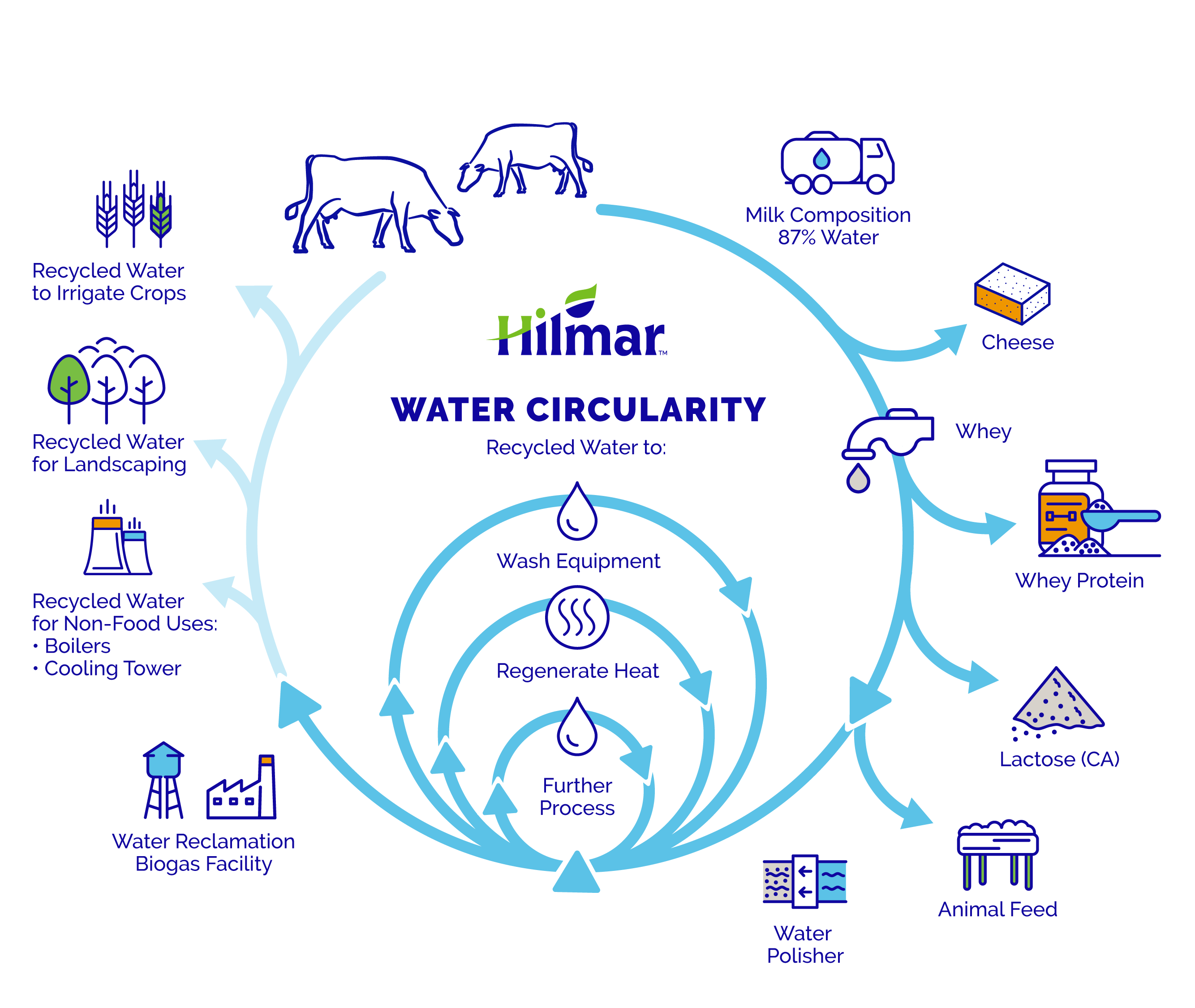

Water

More than 60% of the water we use at our facilities is reclaimed and recycled. Our water recycling process begins with dairy cows, who produce milk that’s 87% water. We separate the solids to make cheese, whey protein, and lactose or animal feed, and then polish the remaining water. This recycled water is used to wash equipment and facilities, and generate steam in our boilers. All wash water then goes to our on-site Water Reclamation facilities, where it’s converted into bio-gas and recycled water for non-food uses, landscaping and to irrigate crops to feed the cows.

Solar Energy

Solar provides more than 20% of the energy for our LEED® (Leadership in Energy and Environmental Design) Platinum Headquarters and Innovation Center.

Social

Sustainability

Community Outreach

We support many organizations to improve lives in our communities. We made Merced County’s “largest” (in size) donation, a 30,000 gallon silo to the Merced County Fire Department for their new Castle Training Facility.

Inspiring Young Minds

We support and encourage education! From our visitor center’s free school field trip program to participation in agriculture and career days to scholarships, 4-H, FFA and more, we believe in continuous learning.

Food Security & Healthier Lives

We support our neighbors in need. We regularly supply our local food banks and contribute to improve health care.

Arts

Music and the arts enrich our lives. We support local events and programs to improve lives.

OUR EMPLOYEES

We take care of our employees and their families. Besides great benefits, our training and advancement program provides opportunities to learn and grow. Our tuition reimbursement program helps employees expand their horizons. Employees also receive recognition for safety, contributions and dedication.

Economic Contribution

Sustainability means stability and economic contributions. Food production is an essential business. We are a reliable supplier to both our domestic and international customers.

Milk Suppliers

We purchase milk from independent dairy farm families who focus on healthy cows, sustainable farms and efficient product to help us achieve our sustainability goals.